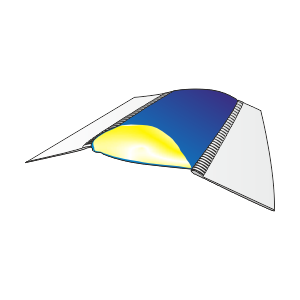

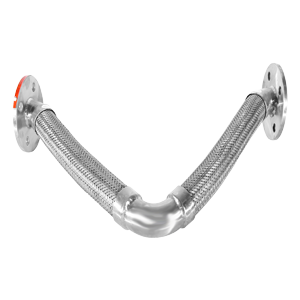

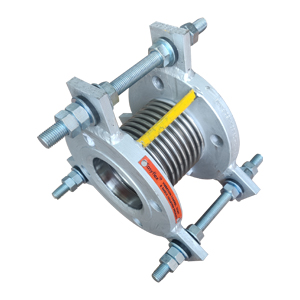

EFSVC” Connectors are one of the most effective ways to compensate for thermal expansion or the unpredictable pipe movements encountered during seismic activity. Series “EFSVC” Flexible Connectors are seismic connectors engineered to absorb movement in all directions. The unique “EFSVC” design places the flexible leg at 45 degree angles to the pipe run, even allowing up and down movements.

Position & Support

- The standard position is with the V and 90 degree elbow hanging down.

- Horizontal and vertical mounting yields the same allowance for motion provided the 90 degree elbow is supported properly to avoid sagging or torquing

- “EFSVC” Connectors larger than 1-1/2” diameter must be supported if installed in any other position than the standard position. Supporting cable or rod should be attached to an eyelet located at the bottom of the 90- degree elbow which can be provided by the factory. Flexible cable or pipe hanger rods can also be used.

- Horizontal Run – “EFSVC” Connector Hanging Straight Down (as illustrated): Loop hangs straight down, without restriction, and free to flex. Support of the bottom elbow is not required. Pipe alignment guides are required to direct axial motion.

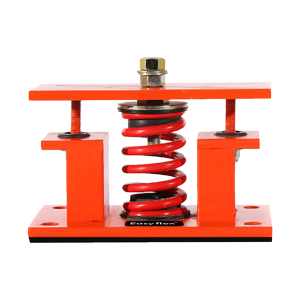

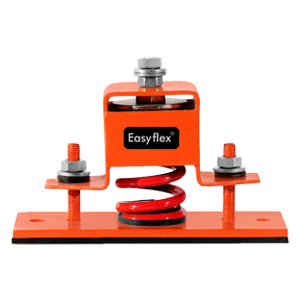

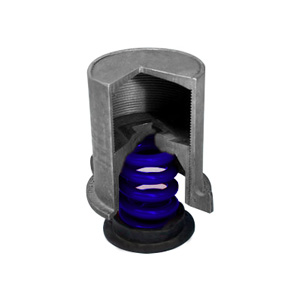

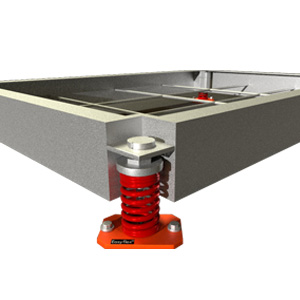

- Horizontal Run – “EFSVC” Connector Straight Up: Support must be provided at the 90 degree elbow to prevent the loop from leaning. Pipe hanger rod or cable must be loose enough to allow the 90 degree elbow to move up or down ¼” as the connector flexes. Spring isolated rod is ideal for this application.

- Horizontal Run – “EFSVC”Connector Horizontal: Support must be provided at the 90 degree elbow to prevent the flex hose from drooping or torquing the hose or pipe. Pipe hanger rod or cable must be loose enough to allow the 90 degree elbow to move horizontally back and forth ¼” as the connector flexes. Spring isolated rod is preferred for this application

- Vertical Run – V Connector Horizontal: Support must be provided at the 90 degree elbow to prevent the flexible hose from drooping or torquing hose or pipe. Pipe hanger rod or cable must be loose enough to allow the 90 degree elbow to move horizontally back and forth ¼” as the connector flexes. Spring isolation rod is preferred for this application.

Expert Advice for Your Application

No two Applications are the same. We will be happy to go over your application in detail and discuss the possibility of using this product for your application. Would you like some personal advice or do you have any questions? We look forward to supporting you.

.jpg)

.png)

.png)

.png)