Hose Assemblies

Metal hoses are useful in a variety of different industrial applications including the transfer of air, gas and fluids. It is also used to balance thermal pressure and help with misalignment issues. Easyflex designs and manufactures high-performing metal hose assemblies that provide longevity, flexibility and strength to any application. We offer a broad range of corrugated inner core diameters and designs, multi braiding capabilities, and engineered assembly expertise to meet to most challenging applications.

Proper hose and fitting selection are critical to the safety of both your people and your profits, thus why the S.T.A.M.P.E.D acronym was created. The STAMPED acronym is an industry-wide standard that should begin every conversation when selecting a hose for a new application. STAMPED stands for: Size, Temperature, Application, Material, Pressure, Ends and Delivery.

What is the hose inside diameter (I.D.) and length required to meet the application requirements? (i.e. 50mm ” x 300 mm ). Size is one of the most critical pieces of information to gather when making hose assemblies. We have hose professionals on-site to ensure you get the correct hose assembly for your specific application.

What are the maximum & minimum temperatures of the product conveyed through the hose assembly, including cleaning and environment? Temperature is extremely important when selecting the correct hose for the application at hand.

What is the hose being used for? Application refers to the environment in which the hose will be exposed to. This includes the configuration, orientation, routing and aspect of the hose. Other considerations include bend radius requirements, flexibility and elongation considerations.

What material or substance will flow through the hose assembly? Specific materials (abrasive, chemical, gases, etc.) often require specific hose design parameters to be sufficiently contained and adequately utilized. This is an important piece of information we will need when offering a recommendation for the hose that is suited for the job at hand. Media velocity and flow rate, the chemical and concentration, solids, description and size should also be noted.

What is the maximum working pressure of your application? In the hose world, pressure is typically referred to as PSI (pounds per square inch). Hoses can rated for suction as low as 29.92 in.-Hg (full vacuum) or as high as 20,000 psi for extreme hydraulic applications.

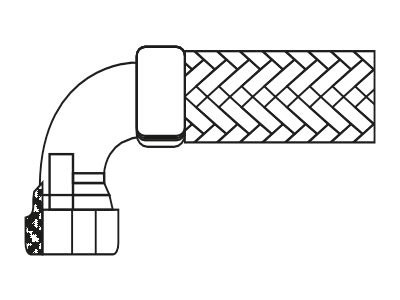

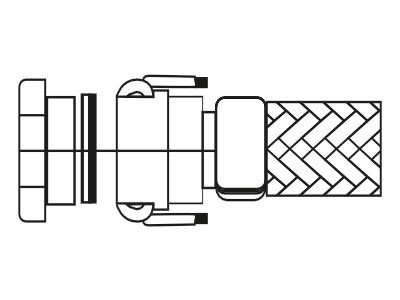

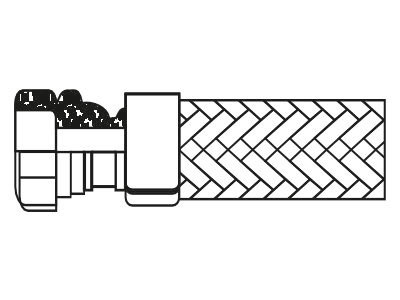

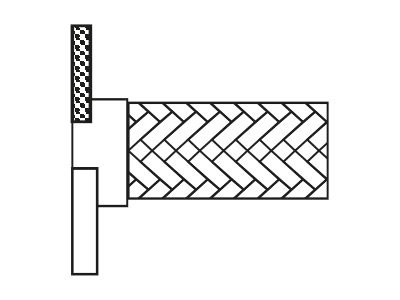

What type(s) of fittings are required for the application? There are various methods for coupling a section of hose with fittings – ranging from male or female, NPT or Pipe Thread, JIC, Sanitary Tri-Clamp, Cam & Groove, Grooved end, etc. The style, type, orientation and attachment methods, among others, are included in this section. Uncoupled or coupled hoses, hoses with built-in fittings, end styles, materials and dimensions, and conductivity requirements should also be noted.

Testing, quality, packaging, certification, shipping and delivery requirements for specific customer.

Easyflex offers a wide variety of custom-built hose assemblies that are assembled in-house and have equipment experts that are trained to assess the needs of any application. Our hose assemblies are engineered to provide reliable presentation while integrating with the other equipment in the processing line to deliver maximum production output.

Flexible Metallic Hose Connections

- Size : 1/4" (6mm) to 12" (300mm)

- Temperature : -200ºC to 700ºC

- Material : Hose S.S. 316/321/304, Braiding S.S. 304

- Material of End connection : M.S., Carbon Steel, brass, G.M. SS 304/304L/316L/321

- Type of End Connections : Threaded Type BSP, BSPT, NPT, NPTF, METRIC, SAE, JIC

- Fittings/Flanges : We can adapt virtually any fittings and flanges to a metal hose - other hose products require special and significant variances. We specialize in providing flexible options. Certified Welding methods: S4041:2006 Class 1 ASME B31.3: 2008 ASME IX:2010 AS/NZS 3992:1998

- End Fittings : Manufactured from Mild Steel, Stainless Steel or Brass. These are fitted by Argon Welding (TIG) or brazing on S.S. Hose depending upon hose type and service conditions to from a complete hose assembly.

Looking for Custom Engineered Metal Hoses? Contact us to request a quote.

Standard Products

-

Heat Pump Fan Coil Rubber Braided Hose Assembly

-

Flexible Connector for FCU-AHU with Brass Ends-2

-

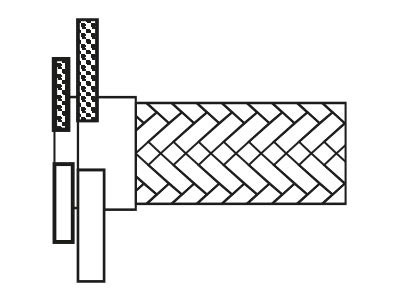

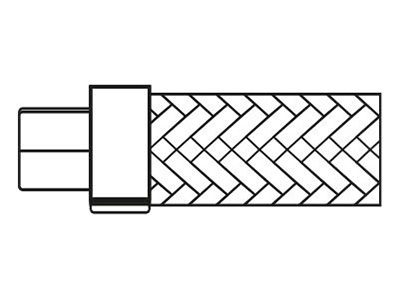

Flexible Metallic Hose Connections

-

SS Braided Connector with Copper Ends

-

Copper & Stainless Steel Vibration Absorbers

-

.png)

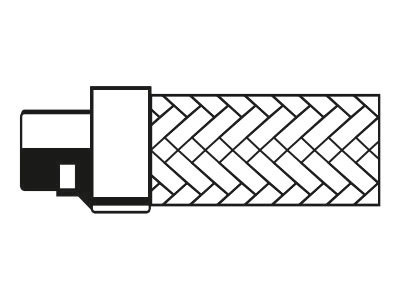

Stainless Steel Braided Flexible Pump Connectors (Type EFMHPC)

-

.png)

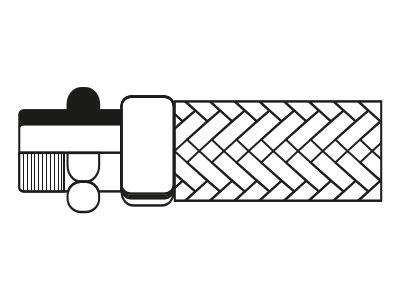

Stainless Steel Braided Flexible Pump Connectors (Type EFMHPC-GC)

-

.png)

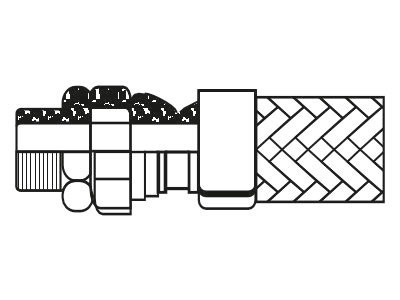

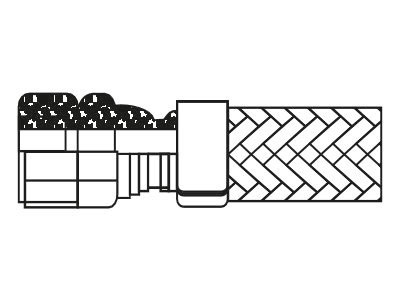

Stainless Steel Braided Flexible Pump Connectors (Type EFMHPC-TC)