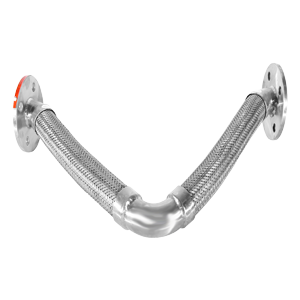

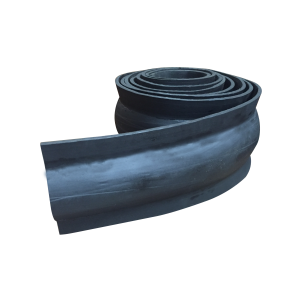

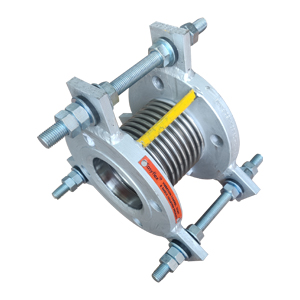

Easyflex Rubber expansion joints, also known as rubber bellows, are key players in a variety of applications, offering a crucial solution for managing movement, vibration, and misalignment in pipelines and ducting systems. Easyflex rubber expansion joints are designed to absorb movement in piping and ducting systems. They are the dynamic components that flex, stretch, and compress to compensate for the forces generated by thermal expansion, pressure fluctuations, and mechanical vibrations. These joints are made from high-quality rubber compounds, making them resilient, cost-effective, and highly versatile.

Easyflex Rubber expansion joints offer several key advantages

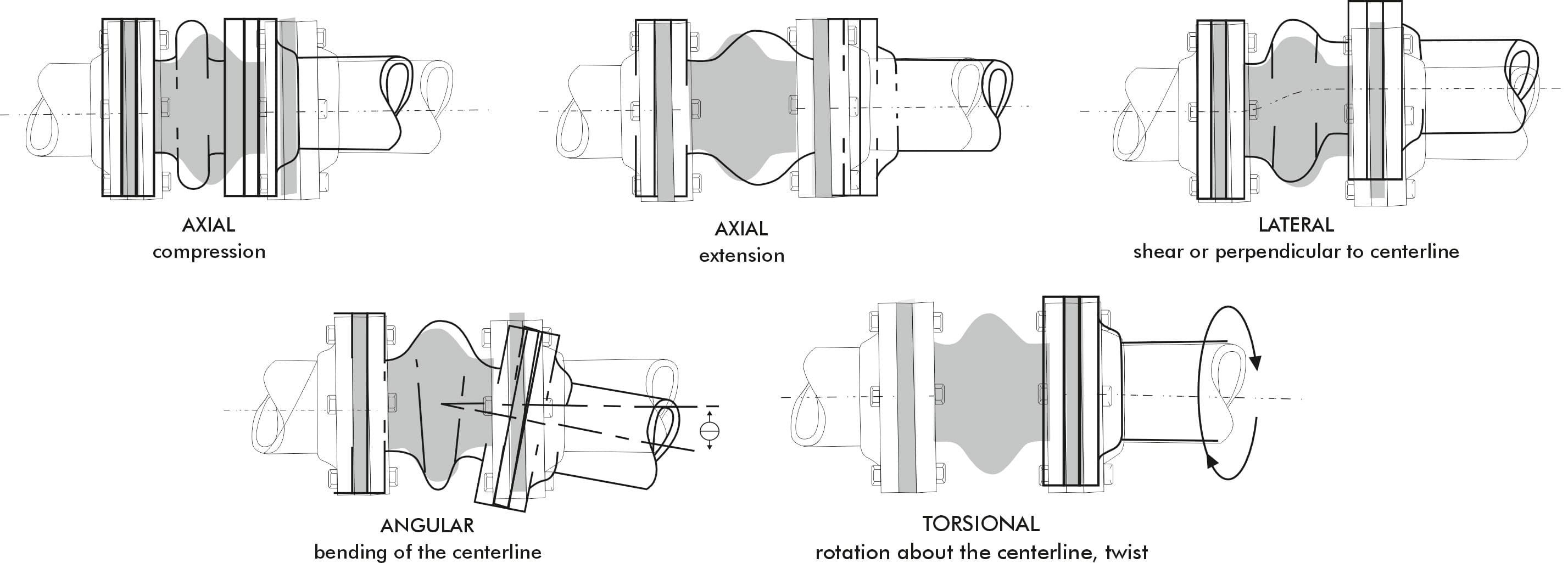

- Flexibility: Their rubber construction allows them to handle various types of movement, including axial, lateral, and angular.

- Vibration Isolation: They effectively dampen vibrations, protecting the integrity of your system and reducing noise.

- Corrosion Resistance: Rubber expansion joints are highly resistant to corrosion, making them suitable for a wide range of environments, including chemical and industrial applications.

- Cost-Effectiveness: They provide an economical solution for managing movement in systems compared to rigid alternatives.

- Easy Installation: Rubber expansion joints are relatively simple to install and require minimal maintenance.

Construction

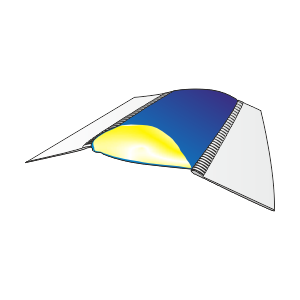

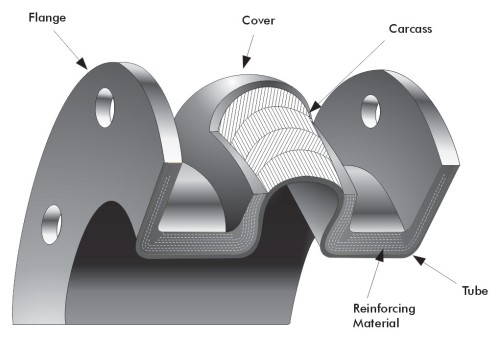

Easyflex Rubber Expansion Joints are designed and manufactured in various polymers according to the need of the application and as per client specifications. If required, Easyflex can design according to any design code specified. The design and construction of the Rubber Expansion Joint is based on the application, flowing media and operating conditions – and also taking the following factors into consideration: chemical resistance of internal layers, weather, ozone and UV-resistance of external layers, temperature and pressure resistance and movement absorption capabilities.

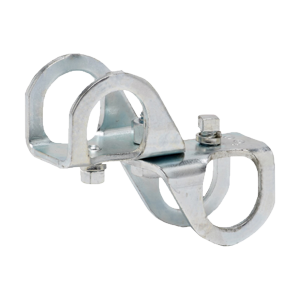

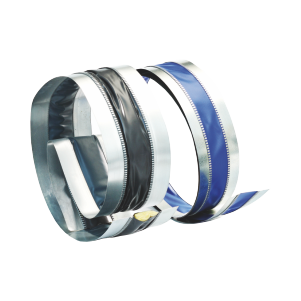

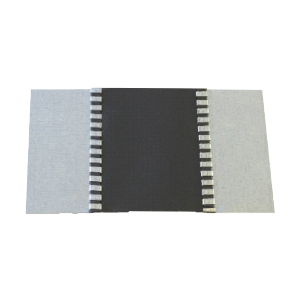

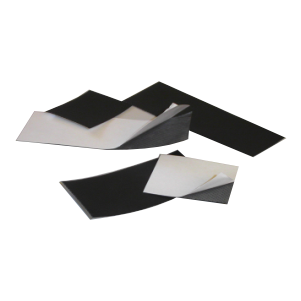

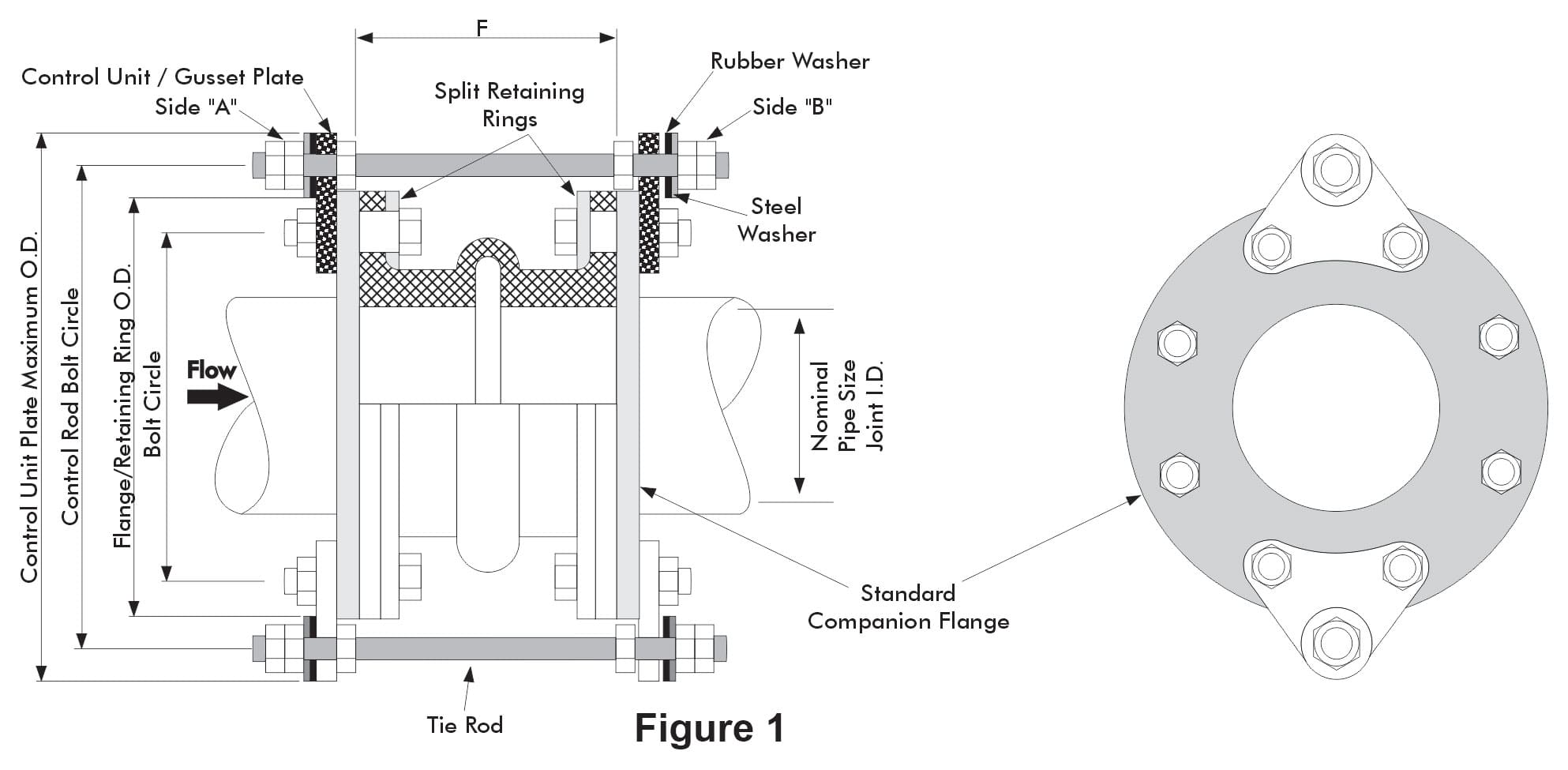

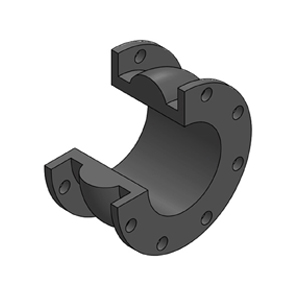

Rubber Expansion joints are build up by an outer cover and an inner cover which is medium resistant and then reinforcement which is pressure resistant. Depending on the design data further accessories such as: vacuum supporting rings, inner sleeve, tie rods, gimbals etc. can be applied.

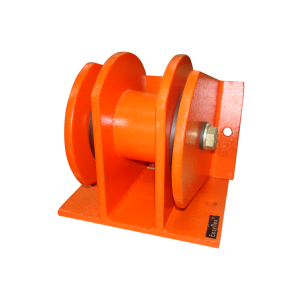

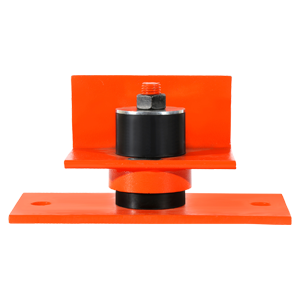

Accessories

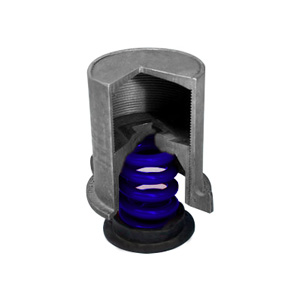

Control Rod Applications: Control rod assemblies are designed to absorb static pressure thrust developed at the connector thus minimizing possible failure of the connector or damage to the equipment. When used in this manner, control unit assemblies are an additional safety factor, minimizing possible failure of the expansion joint or damage to the equipment.

- Anchored Systems: Control rod assemblies are not required in piping systems that are anchored on both sides of the connector provided piping movements are within the rated movements.

- Unanchored Systems: Control rod assemblies are always recommended in unanchored systems and when the maximum pressure and movement exceeds the rated limit.

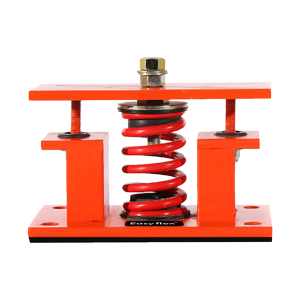

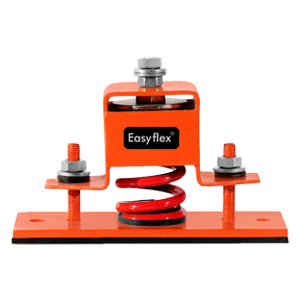

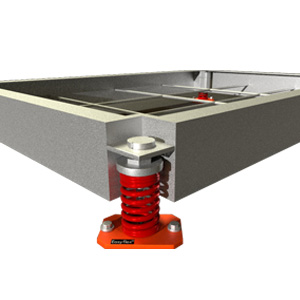

- Spring-Mounted Equipment: Control rod assemblies are always recommended for spring-mounted equipment when the maximum pressure and movement exceed the rated limit.

Flexible pipe connectors shall be used on all piping connected to rotating equipment to reduce the transmission of noise and vibration, and to eliminate stresses in piping systems due to misalignment and thermal movement of the piping. Neoprene based flexible connectors shall be of the single- or double-sphere molded joint configuration and shall meet or exceed specifications of the Rubber Expansion Joint Division, Fluid Sealing Association.

Types REJSA, REJDA, REJFF, EFTSC, EFTSCU connectors shall be made of molded EPDM/NEOPRENE reinforced with nylon tire cord and shall have mild steel floating flanges or female union ends. Control rods shall be used with unanchored systems or with spring-mounted equipment where the pressures and movements exceed those the connectors are designed to withstand.

Flexible connectors shall be EASYFLEX types REJSA, REJDA, REJFF, EFTSC, EFTSCU as manufactured by Kanwal Industrial Corporation.

Expert Advice for Your Application

No two Applications are the same. We will be happy to go over your application in detail and discuss the possibility of using this product for your application. Would you like some personal advice or do you have any questions? We look forward to supporting you.

.jpg)

.png)

.png)

.png)