Rubber Expansion Joints

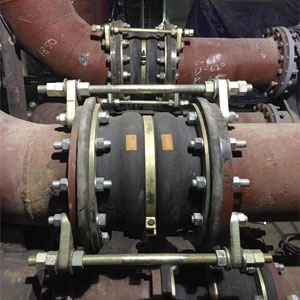

Expansion Joints or Compensators are flexible rubber elements (combined with metal and/or textile reinforcements) useful for conveying fluids and absorbing movements between sections or pipeline. With a correct design they are able to absorb axial, lateral and angular movements offering both safety and insulation against noise and vibrations.

We offer the market the most comprehensive selection of rubber expansion joints, covering the widest range of applications and dimension. By adapting the latest rubber and fabric technology, Kanwal Industrial Corporation can provide the most effective solutions to suit the required needs for any pipe systems.

Rubber expansion joints are used in various systems including: heating, air-conditioning and ventilation systems (HVAC); waste water & sewage treatment plants; power plants; refineries and petrol industry; chemical plants, laboratories and research facilities; ship-building and many other industries. When buying or supplying rubber expansion joints, it is always important to consider the following factors:

- Chemical resistance of internal layers;

- Temperature resistance of internal layers;

- Pressure-resistant reinforcing fabrics;

- Weather conditions;

- Ozone and UV-resistance of external layers

Outstanding features like high absorption of movements in any plane and excellent noise and/or vibration reduction makes them an excellent technical choice. Easyflex rubber expansion joints are versatile and convenient solutions for most piping systems, providing high flexibility, wide movement compensation, good environmental resistance and easy installation.

Floating Flange

Single Arch

Double Arch

U Type

Twin Sphere Connector

Triple Arch

Concentric

Eccentric

Rectangular

One Piece

Outstanding Advantages

- Variety of polymers available

- Internationally approved design as per FSA

- Positive sealing for leak free operation

- Eliminates stress or expansion & contraction

- Compensates for misalignment-axial, lateral, angular & torsional

- Absorbs vibration & shock

- Eliminates line noise

- Prevents pipe buckling & fracture

- Prevents electrolytic corrosion

- Stops water hammer

- Low deformation under pressure

- Greater recovery from movement

- Abrasion, water, heat, chemical, weather resistant, resistant to fatigue

- Negligible loss of heat

AXIAL Compression

AXIAL Extension

LATERAL Shear or Perpendicular to Centerline

ANGULAR Bending of the Centerline

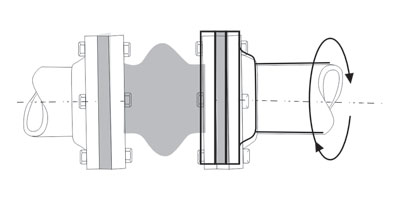

TORSIONAL Rotation About the Centerline, Twist

How A Rubber Expansion Joint Works

The purpose of an Expansion Joint in general, regardless of design or materials of construction, is to provide a point of flexibility in a piping or duct system in order to absorb the growth of the piping due to thermal changes in the media and/or the environment, and to absorb the dynamic movements of machinery, buildings and structures that the piping is attached to or a part of.

The Rubber Expansion Joint, because of the non-metallic nature of its construction, offers the piping and ductwork designer advantages within the temperature and pressure ranges of these joints, which cannot be matched by all metal expansion, joints.

Consisting of flanged ends and a flexible section, much the same as a flanged metal bellows, the rubber expansion joint can absorb within its free length more movements, particularly lateral, than any other joint of similar overall size and pressure rating.

The flexible section of a Rubber Expansion Joints is most often a single convolution, which, because of the inherent flexibility of the materials, can accept large lateral movements with low force, a phenomena which requires multiple convolutions in metal bellows. During axial and angular movements, the rubber convolution deflects much the same way that the metal convolution does. The limits of these motions are determined by the geometric shape and size of the convolution and the inherent pressure resisting capacity of the design.

The manner in which the pressure loads are resisted in a Rubber Expansion Joint is the major difference between Rubber and Metal Bellows. Circumferential (hoop) loads due to pressure are carried by the convolution itself in metallic bellows. In a Rubber Expansion Joint, the convolution is basically incapable of resisting pressure by itself, but is supported by the adjacent rubber tube with its internal fabric and/or fabric - metal reinforcing, or by the attachment flanges themselves.

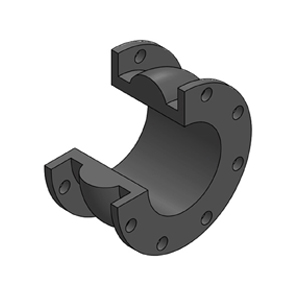

All Easyflex Units have integrally molded flanges, sized and drilled to match standard flanges. All Rubber Expansion Joints require metallic split retaining rings behind the flanges to back up protect the rubber integral flange. Control rods must be used to protect expansion joints from excessive movement if piping system is not properly anchored and are normally recommended for most piping installations.

Applications of Rubber Expansion Joints

HVAC Applications - Rubber expansion joints are used in a variety of heating, ventilation, and air conditioning systems, which includes commercial and industrial buildings, hotels, apartments, schools, shopping plazas and aboard ships to relieve stress in ductwork. Rubber expansion joints are installed to isolate equipment like pumps, compressors and chillers from the piping system. A variety of configurations of joints are available accommodating different shapes, service and connection requirements.

Process Piping - Protection of a process piping system is an important use for rubber expansion joints. The joints reduce noise and vibration caused by forces in pumps. They also centrifuges by behaving as a shock absorber in systems handling abrasive slurries, corrosive chemicals, or very reactive liquids or gases. Thermal movement in a piping system can also be avoided by using rubber joints. The excellent chemical resistance of rubber and synthetic elastomers make these joints ideal for process piping systems.

Power Plant Applications - Nuclear and fossil fuel plants use Rubber expansion joints so as to reduce thermal expansion and contraction on condenser lines, condensate lines, steam turbine exhaust lines, aeration systems and cooling water lines. Reliability, large size capability, long life, and the ease with which they accommodate themselves to movements make these expansion joints ideal for power plant applications.

Industrial Ducting Systems - Rubber expansion joints have been installed in demanding industrial ducting systems where there are problems like heavy vibration, dry or wet corrosive materials, flutter etc.

Marine Systems - Eliminating the destructiveness of electrolysis and at the same time insulating against the transmission of sound, rubber expansion joints allow the necessary motion and flexibility in a 'moving' ship's piping system. The compactness, resilience and low stress features of rubber make these joints ideally suited for shipboard piping systems. The rubber joints are popularly used in areas like auxiliary condenser, air intake on diesel engines, overboard discharge line between condenser and hull, ventilation lines, flush and sanitary systems, fire and bilge pumps, to name a few.

Pollution and Wastewater Treatment - Water treatment plants, waster water treatment plants, Sewage treatment plants, and air scrubber systems all employ the use of rubber expansion joints. Due to their resistance to abrasion and corrosion as well as their flexibility feature, rubber expansion joints are ideal to be used in raw and secondary sewage lines, sludge pumps, centrifugal air blowers, scrub stacks.

Standard Products

-

Single Arch (REJSA)

- Spool “Arch” Type is a full face integral flange design available in both single and double arch types

- Construction is of fabric and rubber, reinforced with metal rings or wires

- Flanges are integral with the body and drilled to conform with the bolt pattern of the metal companion flange

- Face flange is sufficient to form a tight seal without the use of gasket

-

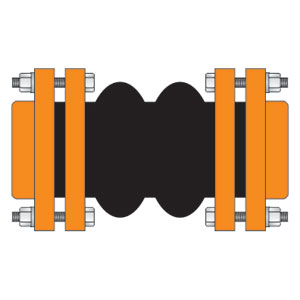

Double Arch (REJDA)

- Spool “Arch” Type is a full face integral flange design available in both single and double arch types

- Joints made of two arches

- May be manufactured to accommodate movements greater than those of which a single joint is capable

- Length of the joint is greater than the single arch model

-

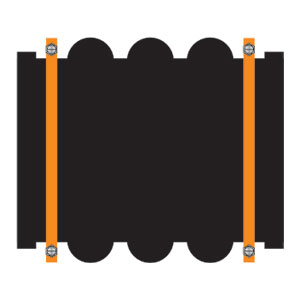

Wide Arch (REJWA)

- Wide arch type features greater movements than the standard spool arch type

- Full face flanges are integral part of the body

- Designed with a weave fabric for pressure resisting strength

- Also available in a metallic and non-metallic reinforced design

-

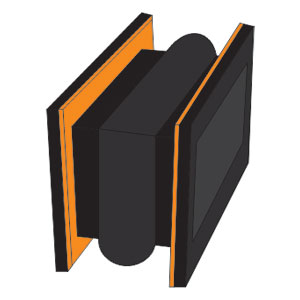

Floating Flange Spherical Molded Single Arch Type (REJFF)

- Designed with a long radius arch to provide additional movement

- Carcass doesn’t contain metal reinforcements

- High burst pressure

- Generally available for pipes sizes under 20”

-

Floating Flange Spherical Molded Single Arch With CU Type (REJFFCU)

- Designed with a long radius arch to provide additional movement

- Carcass doesn’t contain metal reinforcements

- High burst pressure

- Generally available for pipes sizes under 20”

-

Single Sphere Connector Floating Flange length-130mm Type (REJFF)

- Designed with a long radius arch to provide additional movement

- Carcass doesn’t contain metal reinforcements

- High burst pressure

- Generally available for pipes sizes under 20”

-

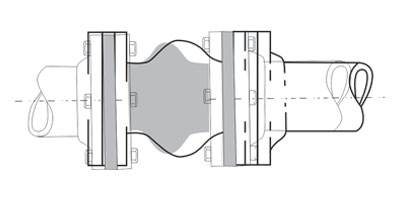

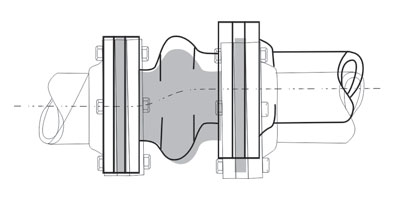

Double Sphere Connector Floating Flange Type (REJFF)

- Designed with a long radius arch to provide additional movement

- Carcass doesn’t contain metal reinforcements

- High burst pressure

- Generally available for pipes sizes under 20”

-

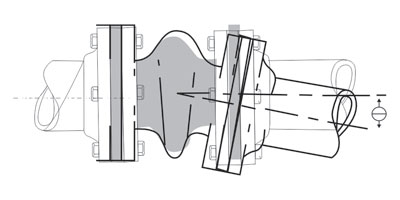

Double Sphere Connector Floating Flange with CU Type (REJFF)

- Designed with a long radius arch to provide additional movement

- Carcass doesn’t contain metal reinforcements

- High burst pressure

- Generally available for pipes sizes under 20”

-

Reduced or Taper Type

- Connects piping of unequal diameters

- Available as concentric or eccentric

-

Filled Arch Type (EFREJFA)

- Inside of arch is filled with rubber

- Filled arch decreases joint flexibility by 50%

- Used to protect from abrasive slurry

-

Twin Sphere Connectors with Threaded Unions (EFTSCU)

- Efficient noise and vibration isolation

- Ability to absorb large displacement due to eccentric, axial, and angular movement

- Applicable for both suction and discharge

- Female Threaded Unions allow for easy installation

-

Expansion Joints for Drainage & Plumbing

- Designed for High Axial & Lateral Movements

- Easy to Install Clamped End Connections

- Customised lengths available

-

Rubber Sleeves

- Reinforced with Polyster Tyre Cord Fabric

- Developed for Steel plant

- High strength sleeves

- Food Grade Applications

- Flanged or Clamped End Connections

- For HVAC Applications

- To ensure conductivity between modules

- Easy to install

-

Silicone Rubber Sleeve

- Food Grade Applications

- Flanged or Clamped End Connections

- White/coloured silicone

-

Rubber Straight Flexible Pipe

- Designed for Long lengths

- Highly flexible

- Available with Swivel flanges

-

Ducting Expansion Joints

- Fully molded rubber duct expansion joints

- Available in round and rectangular configurations

- Ideal for low pressure air & gas applications

- Any dimensions and flange drill pattern can be fabricated

Looking for Custom Engineered Expansion Joints? Contact us to request a quote.