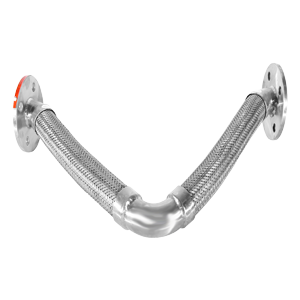

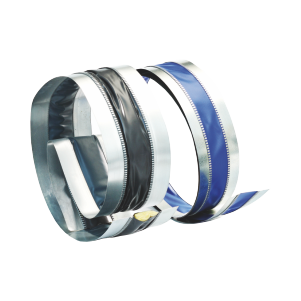

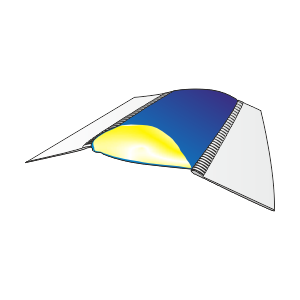

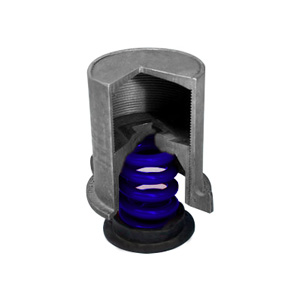

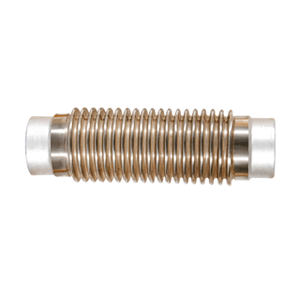

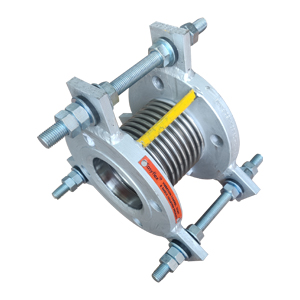

A metallic expansion joint with pipe ends (butt weld type) is a flexible connector designed to absorb movements such as thermal expansion, vibration, and mechanical displacement in piping systems. It consists primarily of a corrugated metal bellows made from stainless steel or other high-performance alloys, which provides the necessary flexibility. The bellows are welded at both ends to integral pipe sections, which are prepared for butt welding directly into the pipeline.

This design ensures leak-tight integrity, making it ideal for high-pressure and high-temperature applications in industries such as power generation, petrochemicals, oil and gas, and process engineering. The butt weld ends allow for permanent and robust connections, minimizing the risk of leaks and ensuring long-term reliability.

Key Features:

- Material: Typically stainless steel (304, 316, Inconel, etc.)

- End Connections: Straight pipe ends bevelled for butt welding

- Functions: Absorbs axial, lateral, and angular movements

- Applications: Steam lines, exhaust systems, chemical processing, and more

- Advantages: High strength, corrosion resistance, and long service life

Overall, metallic expansion joints with pipe ends (butt weld) offer a dependable solution for accommodating thermal and mechanical stresses in critical piping systems.

| Pipe | Pipe | Working | Working | Movement | Spring Rate | Life Cycle | Drawing | |||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| NPS | Size | Length | OD | Thickness | Pressure | Temperature | Axial | Lateral | Axial | Lateral | ||

| (DN) | Inch | Inch | Inch | PSI | ⁰F | Inch | Inch | lb/in | lb/in | |||

| 2 | 50 | 8 | 2.374 | Sch 40 | 150 | 850 | ±0.4 | ±0.08 | 828 | 622 | Above 10000 | Click here |

| 2.5 | 65 | 8 | 2.874 | Sch 40 | 150 | 850 | ±0.4 | ±0.08 | 959 | 1011 | Above 10000 | Click here |

| 3 | 80 | 8 | 3.5 | Sch 40 | 150 | 850 | ±0.4 | ±0.08 | 685 | 1068 | Above 10000 | Click here |

| 4 | 100 | 8 | 4.5 | Sch 40 | 150 | 850 | ±0.4 | ±0.08 | 857 | 2067 | Above 10000 | Click here |

| 5 | 80 | 8 | 5.563 | Sch 40 | 150 | 850 | ±0.4 | ±0.08 | 1045 | 3712 | Above 10000 | Click here |

| 6 | 150 | 10 | 6.626 | Sch 40 | 150 | 850 | ±0.4 | ±0.08 | 1913 | 4534 | Above 10000 | Click here |

| 8 | 200 | 10 | 8.626 | Sch 40 | 150 | 850 | ±0.4 | ±0.08 | 1662 | 6698 | Above 10000 | Click here |

| 10 | 250 | 10 | 10.752 | Sch 40 | 150 | 850 | ±0.4 | ±0.08 | 1993 | 12106 | Above 10000 | Click here |

| 12 | 300 | 10 | 12.752 | Std /0.39" | 150 | 850 | ±0.4 | ±0.08 | 2535 | 21624 | Above 10000 | Click here |

| 14 | 350 | 10 | 14 | Std /0.39" | 150 | 850 | ±0.4 | ±0.08 | 2809 | 36347 | Above 10000 | Click here |

| 16 | 400 | 10 | 16 | Std /0.39" | 150 | 850 | ±0.4 | ±0.08 | 3078 | 50974 | Above 10000 | Click here |

| 18 | 450 | 10 | 17.992 | Std /0.39" | 150 | 850 | ±0.4 | ±0.08 | 3358 | 69567 | Above 10000 | Click here |

| 20 | 500 | 10 | 20 | Std /0.39" | 150 | 850 | ±0.4 | ±0.08 | 3677 | 93058 | Above 10000 | Click here |

| 24 | 600 | 10 | 24.016 | Std /0.39" | 150 | 850 | ±0.4 | ±0.08 | 5613 | 155442 | Above 10000 | Click here |

Material of Construction:

Bellow : A 240 Gr.304

Butt Weld End : ASTM A 106/ IS 2062 Gr. B

Notes:

1. Bellow Design & Tolerance is as per EJMA 10th Edition.

2. Shipping bar will be provided painted in yellow, removed it after installation.

3. All surface will be smooth finish,free from welding burrs and Sharp edges.

Testing:

1. 100% Die penetration test on weld joints where ever applicable.

2. Raw material check test for chemical composition and mechanical

3.Hydrotest will be done at 1.5 times Working Pressure

4. Dimension and visual check.

Expert Advice for Your Application

No two Applications are the same. We will be happy to go over your application in detail and discuss the possibility of using this product for your application. Would you like some personal advice or do you have any questions? We look forward to supporting you.

.jpg)

.png)

.png)

.png)