Metallic Expansion Joints

Bellows are a flexible piping element. The corrugation of the expansion joint is designed to be flexible in order to absorb pipe expansion and contraction due to changes in temperature. The number of corrugation of bellows is decided according to the displacement amount and the expansionary and contracting force that the bellows have to absorb. Bellows have to be strong to the design pressure and operating pressure of piping and installation and they also have to be flexible to absorb thermal movement. The thrust force of the flow in the piping has to be buttressed by things other than bellows.

The value of the thrust force of bellows is usually calculated by multiplying the value of the effective cross section area by the value of the flow pressure of pipe.

Kanwal's Easyflex Bellows are fabricated from cylindrical tubes made of high ductility material. The cylindrical body is formed onto parallel corrugations which accommodates all basic movements without encountering wear and tear as associated with conventional mechanical devices. Bellows are designed and manufactures as per the latest additions of EJMA, ASME, GIS, S, DIN, IS standards under the supervision of highly qualified team of engineers and technocrats.

To attain high flexibility and above average life expectancy, our Bellows are made from tested S. S. 316/321/304 stainless steel material. These bellows retain the flexibility when subject to internal pressure. Kanwal's Easyflex Bellows have proven their outstanding performance in a wide variety of applications.

Operating Mechanism of Metallic Expansion Joints

Why Expansion Joints are Required

While designing pipelines, a main artery of the modern industry, planners always face many obstacles: the expansion and contraction of pipes caused by temperature changes both external and internal, vibrations generated from machine operation and other stress imposed on the pipelines by wind or in some cases by earthquake. Therefore, protection from these hazardous elements is always of major interest to the pipeline engineers.

To absorb pressure from expansion, contraction and the vibration of pipes, flexibility is key. One of the most effective flexible elements is the metallic bellows type expansion joint, which is currently widely used due to continued developments and improvements in the performance and design technique.

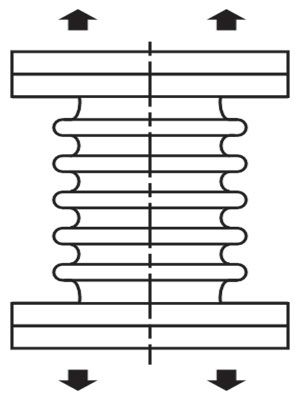

Axial Elongation

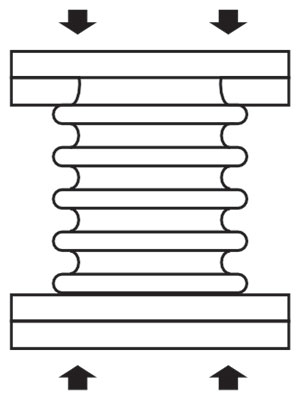

Axial Compression

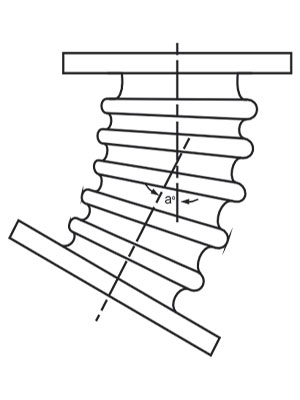

Angular Movement

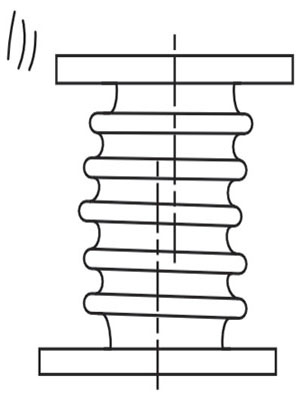

Lateral Movement

-

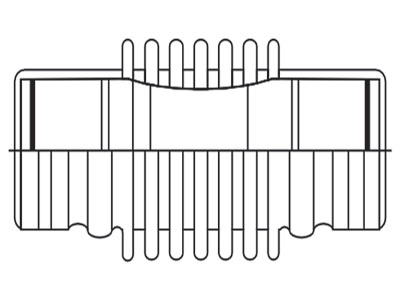

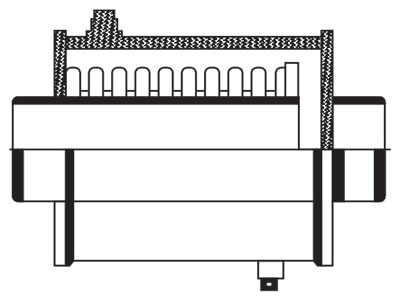

Single Bellows Assembly

A bellows with end connections, designed to absorb all movements of the piping system in which it is installed.

-

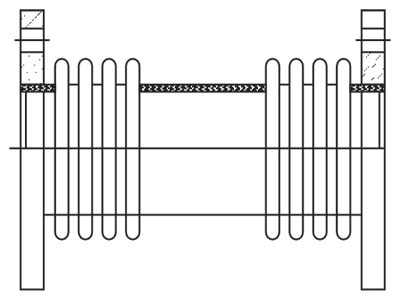

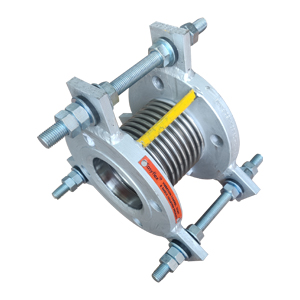

Universal Expansion Joint Assembly

A universal expansion joint is an assembly containing one or two bellows connected by a center pipe and equipped with tie rods.

-

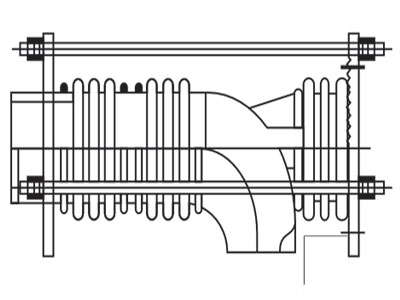

Hinged Bellows Assembly

A hinged expansion joint is an assembly designed to absorb angular rotation in the plane perpendicular to the hinge pins

-

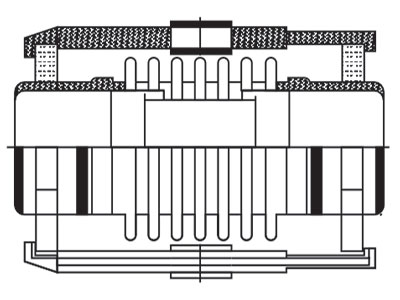

Gimbal Bellows Assembly

A Gimbal Expansion Joint is an assembly designed to absorb angular movement in any plane.

-

Pressure Balanced Elbow Assembly

is an assembly designed to absorb axial movement while the pressure thrust is balanced by means of tie rods.

-

Externally Pressurized Assembly

for high pressure applications with long axial movements

Looking for Custom Engineered Expansion Joints? Contact us to request a quote.

Standard Products

-

Exhaust Expansion Joints

-

PN10 & PN16 Metallic Expansion Joints

-

PN20 & PN25 Metallic Expansion Joints

-

PN25 Reinforced Metallic Expansion Joints

-

PN30 Reinforced Metallic Expansion Joints

-

PN40 Reinforced Metallic Expansion Joints

-

Tied Pump Connectors

-

Universal Expansion Joints

-

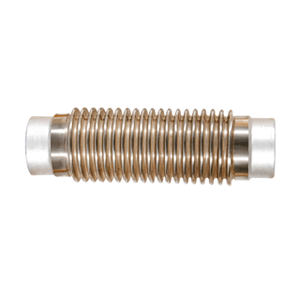

Butt Weld End Bellow

-

Single Axial Expansion Joint with Flange end